Water based floor finish - How to

Water based floor finish system - With new technology on water base polyurethane floor finishes coming out every year. It is always hard to choose the right system that will stand up to abuse and have longevity. You need a finish that will match your lifestyle. Something durable and has exceptional scratch and chemical resistant. Something that will last at least 15 years. Luckily, with new technology, it has become easier and easier to apply high quality products with great long lasting results. You just need to do the proper prep work and floor sanding. And applying a high quality finish is pretty easy. Just how easy? Continue reading and find out.

Waterborne Sealers - Why use it?

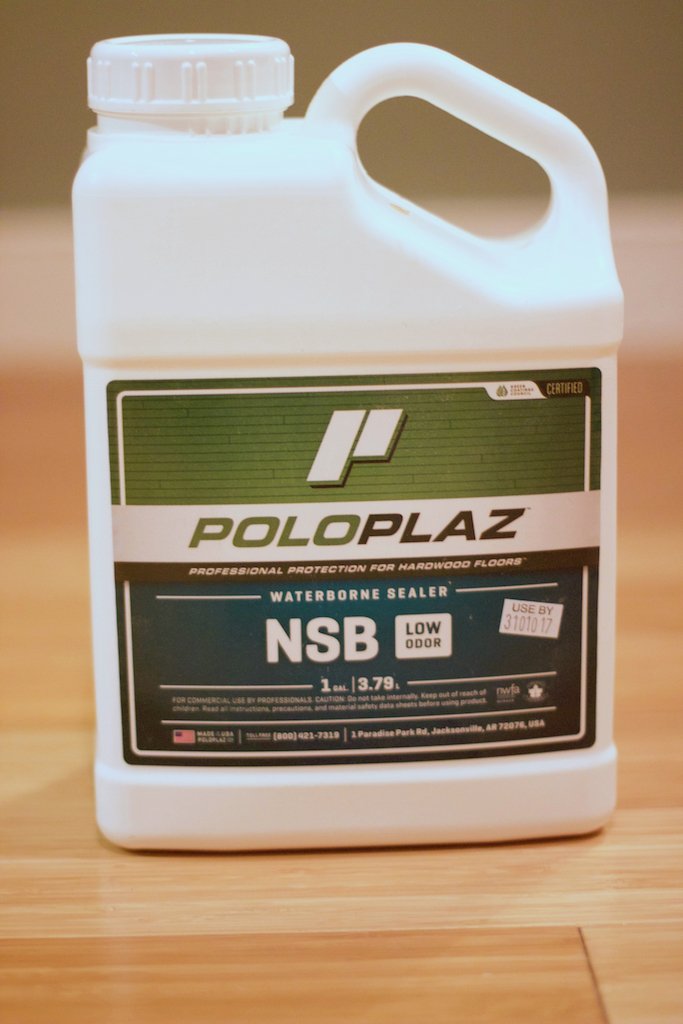

Waterborne sealers, why use it? Simple, because it is what makes a successful water based floor finish system. The sealer enhances the natural tones of the wood and adds additional protection to the polyurethane system. When choosing a wood floor sealer choose a high solid, building sealer and one that will not cause side bonding or panelization. You will get great protection, eliminate tannin pull and maximize your film build from the polyurethane. For, more information on sealers and application, click the link here: Sealers

Application for high build sealers

Sand your wood flooring according to NWFA procedures, making your final cut with 120 grit and clean thoroughly. Unless, you like the feel of sandpaper, sand the floor as smooth as possible. You can apply the sealer using a Nylon brush, water base block applicator, T-bar or roller (1/4" nap mohair or 3/8" nap microfiber ). Apply the first coat at a rate of 500 sq. ft. per gallon. Don't skimp out on the product. Get this stuff down at the proper rate. Otherwise, you will experience all the nightmare and headaches you have been reading about online. Dry brushing, tannin pull, uneven sheen, lines, orange peel effect, etc. Apply with the grain and feather out any start and stop points. Becareful not to leave puddles and drips. Let the first coat dry for 4 hours. The second coat of sealer can be hot coated, no abrading needed. Apply the second coat as the same rate as the first. Allow the second coat to dry overnight. Clean tools with water.

Water based floor finish - Will yours stand up to the test of time?

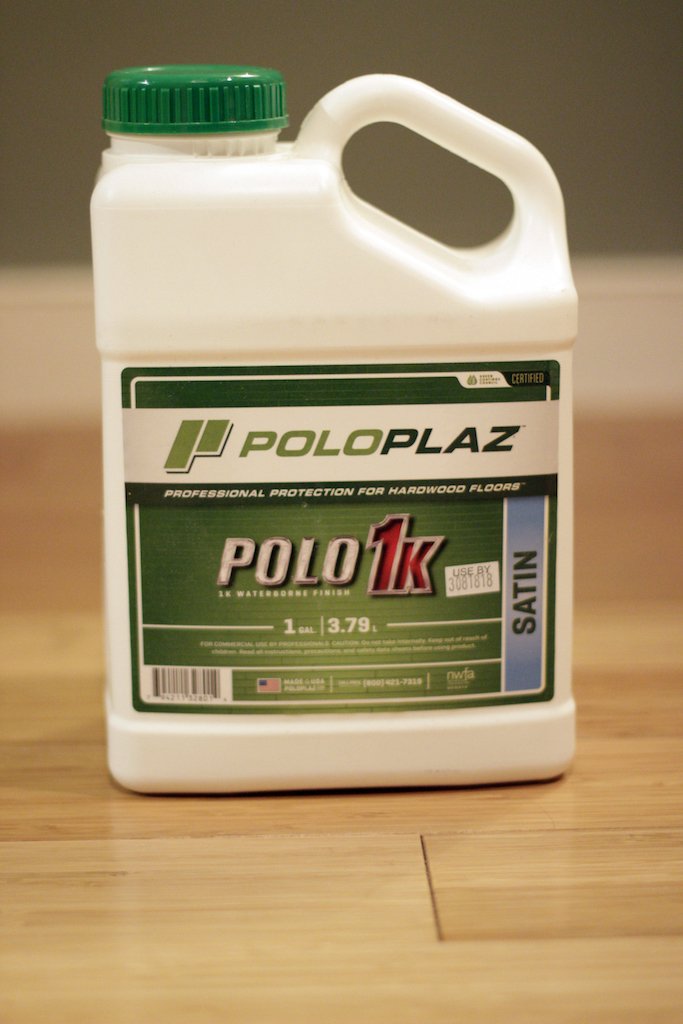

Poloplaz water based floor finish top coat, your first defense against cleaners, spills, dirt, mud, furnitures, pets, friends and family. Will yours stand up to the test of time? If, you are using a high quality system, then no worries needed. Keep reading on for application tips. If, not look into choosing a ceramic, acrylate or aluminum oxide finishes with a fast curing time. The most important attribute is the fast curing. Why? Most polyurethane coatings will get damaged within the first 3o days of use. This is when it is most vulnerable and softest, due to it's long curing period. Shorten that time and the durability reaches full strength sooner. There are finishes that cures from 24 to 72 hours. These are the finishes you want to choose from.

Application for water based floor finish

Dust will show through your polyurethane if, you fall asleep at this stage. Buff and screen your sealer coat with either 180 or 220 grit screen, sanding strips or the use of a multi-head driver. Clean, vacuum and tack thoroughly. Apply your water base polyurethane wood floor finish using a nylon brush, a water base block applicator, T-bar or roller (1/4" nap mohair or 3/8" nap microfiber ). Apply the floor finish at a 400-500 square feet rate coverage. Biggest mistake everyone makes is applying too thin of a coat. Load it on, especially if, you're rolling the product. This will help eliminate missed spots, brush marks and an orange peel effect. Feather out your start and stop points by lifting the applicator. Allow the first coat of poly to dry for 4 hours. No abrasion is needed in-between coats for adhesion. You can hot coat the final coat, only if, the waterborne polyurethane is smooth enough for you. But for a smoother finish, abrade the polyurethane with either 180 or 220 grit screen, sanding strips or the use of a multi-head driver. Then clean, vacuum and tack thoroughly. And then apply the final coat at the same rate. Let it dry overnight, before applying light foot traffic. Tools can be cleaned with water.

Water based floor finish : Maintenance and clean up

Just applying a high quality finish is only part of the polyurethane floor finish system. Maintenance and clean up makes up the rest. With improper maintenance and clean up, don't expect your newly finished water based floor finish to last 15 years. Here are some tips to help you maintain your wood floor finish: felt pads, you can never have enough and be sure to use a slightly bigger size for your furniture legs, for daily cleaning use a dry microfiber mop, use a non-diluted cleaner specifically for hardwood floors: it dries faster and will not cause cupping, stay away from polishes or anything that will add a shine: this stuff leaves a residue, use breathable floor mats at entries and sinks, stay away from products with high ph balance: these break down your finish, always use a ph neutral cleaner. Your finish is on it's way to longevity.

For more information and tips on cleaning wood floors click on here: hardwood floor care

Choose an ideal company

You have done all the research and now have the knowledge. Don't choose the wrong flooring company.

Why work with average, when you can work with an ideal hardwood flooring company? Avoid opting for sub-par products, poor workmanship, the lack of industry knowledge and training for the sake of something new.

With G & S Floors, you will experience optimum personal service, with superlative, effective premium quality workmanship in the industry and high quality products. Homes are one of the biggest and most important investments and should be cared by an ideal company.

We've been in business over 19 years. We are a NWFA flooring contractor and follow industry standards and best practice for hardwood flooring installation, sand and finishing. We have access to training and ongoing professional development. We have a well trained staff and we never stop learning. We have a powerful network of talented professionals, distributors, manufactures and experts.

Invest in "Quality" for better service and hardwood flooring that can last a lifetime or centuries!